Internal crystallization method

1.

Introduction

Single-crystalline

eutectic oxide fibres are needed to reinforce metal,

intermetallic and ceramic matrices to obtain high temperature composites.

2.

The fundamentals of the internal

crystallization method

The method of internal

crystallization was developed in Laboratory of Reinforced Systems of Solid

State Physics Institute initially to produce oxide-matrix/molybdenum-matrix

composites, which were considered mainly as model ones. The concept of the

method is illustrated in Figure 1.

Figure 1. Schematic of the

internal crystallization method (ICM).

First of all a molybdenum

carcass with continuous cylindrical channels is obtained by diffusion bonding

of an assemblage of molybdenum wires and foils. The carcass is then put into

contact with an oxide melt; capillary forces yield the infiltration of the

channels with a melted fibre material. The oxide/molybdenum block is then

moved to a cold zone of the furnace to crystallize the fibres. This is the

basic scheme of the ICM [5 ,6], a variation of the basic scheme with single

crystalline seeds at the top of the carcass (Figure

2) allows obtaining a fibre set of a homogeneous crystallographic

orientation [8]. The final step in the obtaining fibres process is dissolution

of molybdenum in an HCl/HNO3/H2O mixture.

Figure 2.

A set of the molybdenum

carcasses with seeds at the top.

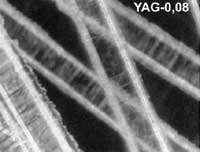

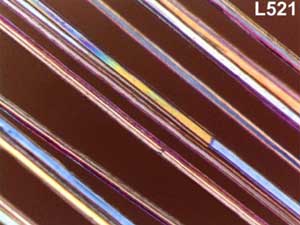

A variety of the oxide fibres,

such as sapphire [8 ] and YAG [9 ] of a homogeneous crystallographic

orientation alumina-YAG eutectic [7 ], and single crystalline mullite [10 ]

have been obtained by using the method.

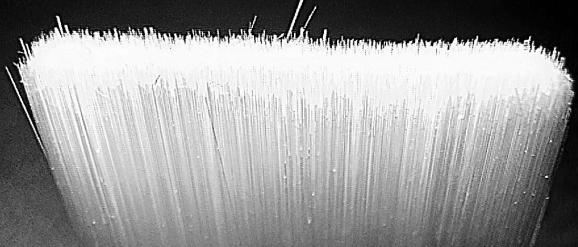

Some illustrations of the fibres obtained are presented in

Figure 3

.

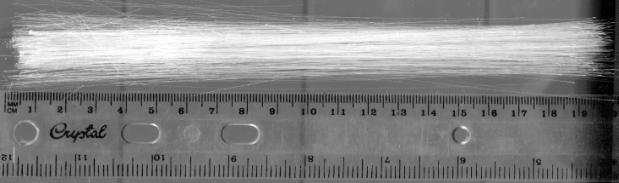

A bounded

bundle of sapphire fibres.

A bounded

bundle of sapphire fibres.